ABOUT US

OUR HISTORY

Founded in 2004, DSW Industry is a professional die-casting supplier for casting and machined parts, widely used in the automobile, medical, machine equipment, petroleum, and electricity Industries.

With over 15 years of diverse manufacturing experience, DSW industry specialises in high-pressure die casting for aluminium and zinc, investment casting for alloys and various metals, precision machining, and tool and fixture design. We are a trusted and proficient partner in these expert fields, offering industry-specific expertise and reliability.

- Quality

- Accuracy

- Safety

- Reliance

OUR PROJECTS

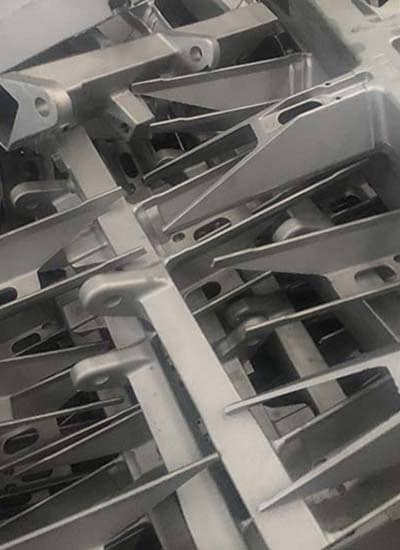

Die Cast For Industry

DSW is ISO 9001 certified, demonstrating their commitment to maintaining high standards of quality management.

ABOUT US

MISSION & VISIONS

Our mission is to be a leading provider of high-quality die cast components, delivering exceptional value to our customers through innovative solutions, superior craftsmanship, and unmatched customer service. We are committed to continuous improvement, operational excellence, and fostering long-term partnerships with our clients.

- ManpowerSkilled and experienced

- MachineryWell-equipped & conditioned

- MaterialsQuality & consistency

- MethodsMaintain the quality

WHAT THEY SAY?

TESTIMONIALS

We’d been having trouble with another die casting supplier in China—their prices were high and deliveries kept slipping. This new team stepped in, used our existing die, and produced quality parts. I’m looking forward to working with them for well-priced, reliable components and building a solid, long-term partnership.

Hauss ArmandTELE Technology

DSW Industrial came through for us—they got the die casting tooling done in just 8 weeks. They also helped a lot with the design and development aspects. Super easy to work with.

Michael HawksGF Industrial

They’ve been a great die casting supplier from China — fair prices, good quality, and always deliver on time. If you need die cast parts from China, I’d definitely recommend them. They’ve even done special runs for us and sped things up when we were in a tight spot.

Nicolas CageIPU Industry

RESULTS

DSW strives to be the preferred die casting partner, known for expertise, reliability, and exceeding customer expectations.

We invest in technology, foster innovation, and uphold quality and sustainability, driving customer success and industry growth.

We’re Hiring, Join Our Talent Team

Feel free to contact us and send your resume

DSW specializes in die casting for aluminum and zinc alloys, gravity and investment casting for various metals, precision machining, and tool and fixture design.

We cater to a diverse range of industries, including automotive, medical, machinery equipment, petroleum, and electricity. Our die-casting components are utilized in applications such as lighting, medical devices, and automotive parts.

Yes, our experienced team offers in-house mold design, mold making, machining, surface finishing, assembly, and painting services. We collaborate closely with clients from the initial design phase to the final production to ensure the end product meets their specifications and functional requirements.

The lead time for die cast tooling generally ranges from 4 to 12 weeks and includes the following stages:

- Initial Design – Concept development and specification refinement.

- Mold Fabrication – Precision machining and thorough testing to ensure quality.

- Adjustments & Optimization – Modifications to address defects or enhance performance, which may extend the timeline.