What is a Tool and Die Maker?

A tool and die maker is a highly skilled professional who designs, builds, and maintains the specialized tools, dies, molds, and fixtures used in modern manufacturing. These experts are critical to producing high-precision components across industries such as automotive, aerospace, electronics, and consumer goods.

Tool and Die Maker in Manufacturing

Tool and die makers play a crucial role in the manufacturing industry by fabricating precision tools and dies that are essential for shaping raw materials into finished products. They work closely with engineers, machinists, and production teams to ensure the efficiency and accuracy of manufacturing processes.

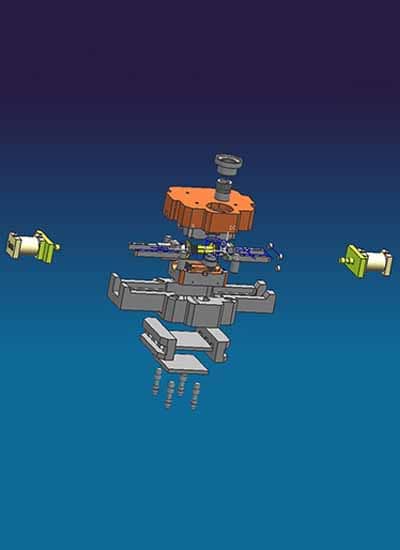

Designing Tools and Dies: Tool and die makers are responsible for interpreting engineering drawings and specifications to design and develop tools, dies, molds, and fixtures. DSW uses computer-aided design (CAD) software and traditional drafting techniques to create detailed plans for manufacturing components.

Machining and Fabrication: DSW, a Tool and die maker uses various machining and fabrication techniques to shape and form materials into finished components. This may involve milling, turning, grinding, drilling, and EDM (electrical discharge machining).

Tools and Dies: Understanding the Difference

A. Definition of Tools and Dies:

• Tools encompass a broad category of mechanical devices used in manufacturing, including cutting tools, forming tools, jigs, and fixtures.

• Dies are specialized tools designed to cut, shape, or form materials, typically metals or plastics, into specific shapes or profiles.

B. Distinction between Tools and Dies: While tools refer to a wide range of mechanical devices used in manufacturing, dies specifically focus on changing the shape or profile of materials during manufacturing processes.

C. Focus and Function of Dies in Manufacturing: Dies specialize in shaping materials to precise dimensions or profiles required for manufacturing products. They ensure accuracy and repeatability when producing components for various industries.

Types of Aluminum Casting Dies

- Permanent Mold Die (Gravity Die)

- Description: Made from steel or iron, used repeatedly for gravity-fed casting.

- Casting Method: Gravity Die Casting

- Applications: Medium-volume production of parts like wheels, housings, and brackets.

- Advantages:

- Good surface finish

- Better dimensional accuracy than sand casting

- Stronger mechanical properties due to faster cooling

- High-Pressure Die Casting (HPDC) Die

- Description: Precision-machined steel dies used with high-pressure injection of molten aluminum.

- Casting Method: High-Pressure Die Casting

- Applications: Automotive parts, electronics housings, consumer goods.

- Advantages:

- High-speed production

- Excellent surface finish

- Ideal for thin-wall components

- Tight tolerances

- Low-Pressure Die Casting (LPDC) Die

- Description: Die designed to fill from the bottom under low gas pressure (typically 0.7 bar).

- Casting Method: Low-Pressure Die Casting

- Applications: Wheels, structural parts, cylinder heads.

- Advantages:

- Good metallurgical quality

- Controlled filling, less turbulence

- Low porosity, suitable for heat-treated parts

- Sand Casting Die (Pattern and Core Box)

- Description: Patterns and core boxes made from wood, plastic, or metal to form sand molds.

- Casting Method: Sand Casting

- Applications: Large, complex parts in low volumes (e.g., engine blocks, pump housings).

- Advantages:

- Low tooling cost

- Flexible for design changes

- Suitable for large castings

- Prototype Die

- Description: Simplified, low-cost die made for trial runs or product development.

- Casting Method: Can be used in gravity or pressure die casting.

- Applications: Pre-production testing of parts.

- Advantages:

- Fast delivery

- Low investment risk

- Useful for design validation

- Semi-Permanent Mold Die

- Description: Combination of permanent mold and sand cores for internal cavities.

- Casting Method: Gravity Die Casting with sand cores

- Applications: Cylinder heads, manifolds, water pump housings.

- Advantages:

- Can form complex internal geometries

- Strong mechanical properties

- Medium production volumes

Manufacturing’s Tool and Die Solutions

DSW Manufacturing specializes in providing comprehensive tool and die solutions tailored to the needs of various industries.

Our services include design, engineering, simulation testing, tool-making, and repair, ensuring our clients receive high-quality and reliable tooling solutions.

Contact DSW Manufacturing today for a quote and discover how our tool and die solutions can enhance the efficiency and quality of your manufacturing processes.

No comment