Zinc Die Casting Services

DSW: High Precision, Superior Properties

DSW specializes in high-quality zinc alloy die casting services, providing solutions for industries such as lighting, consumer goods, medical, automotive, and home appliances. We leverage state-of-the-art zinc alloy casting and machining technologies, backed by in-house design, engineering, and die tool operations, to ensure we meet your exact specifications and deliver exceptional results.

With over 21 years of experience and a modern manufacturing facility, DSW is your trusted partner for precision zinc die casting services. Our capabilities include machines with locking forces up to 500 tons, allowing us to produce zinc parts in sizes ranging from miniature to over 51cm in length.

Zinc Alloy Die Casting

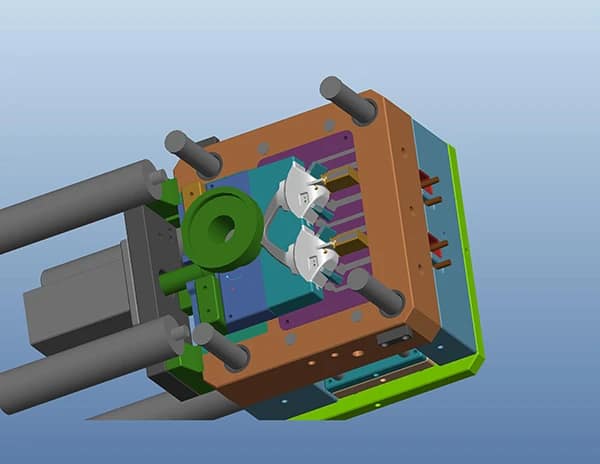

Our factory has 18 die casting machines, ranging from 80 to 2000 tons,

to produce high-quality zinc alloy die-cast parts.

Benefits of Zinc Die Casting?

Offers flexibility, stability, cost-efficiency, and versatile finishes for industries.

Zinc die casting has several advantages over other alloys, such as improved strength, toughness, and cost-efficiency. Its properties often exceed those of aluminum, magnesium, bronze, plastics, and cast iron. Key benefits include:

- Better Castability: Zinc has excellent fluidity, making it ideal for complex shapes.

- Shorter Cycle Time: Rapid solidification speeds up production.

- Longer Die Life: Zinc’s low melting point extends the life of dies, reducing downtime and repair costs.

- Superior Mechanical Properties: Zinc alloys have better yield strength and vibration damping than aluminum.

- Cost-Efficiency: Zinc lowers tooling costs, especially with the high-speed miniature die casting process.

What Are Zinc Alloys?

Perfect for lighting, automotive, electronics, home appliances, and more.

We offer a variety of zinc alloys for die casting, including Zamak #2, #3, #5, #7, ZA8, and ZA27. These alloys are known for impact strength and dimensional stability, making them ideal for various applications.

- Zamak 2: The strongest and hardest of all Zamak alloys, suitable for bearing applications.

- Zamak 3: Offers a balance of strength, castability, and dimensional stability, making it the most commonly used alloy.

- Zamak 5: Stronger and harder than Zamak 3, commonly used in Europe.

- Zamak 7: A high-purity alloy with better fluidity and surface finish.

- ZA-8: Contains 8.4% aluminum and is ideal for components requiring high aluminum content.

- ZA-27: With about 27% aluminum, this alloy is perfect for high-strength applications.

For more details, check our Casting Alloy Specifications and Alloy Physical Specifications sheets.

Zinc Alloy Properties and Their Impact on Mould Design

| Property | Description | Implications for Mould Design |

|---|---|---|

| Low Melting Point (approx. 380–420 °C) | Reduces thermal stress on the mould steel | Extends mould lifespan and allows greater flexibility in selecting mould steels |

| Excellent Fluidity | Suits thin-walled or intricate geometries | Demands precise gate and runner design to ensure balanced flow and minimise air entrapment |

| Susceptibility to Oxidation | Risk of surface porosity and gas inclusion | Necessitates robust venting and anti-corrosion cavity treatments |

| High Dimensional Stability | Exhibits minimal thermal shrinkage | Supports consistent component production with tight dimensional tolerances |

| Superior Finishability | Readily plated, painted, or laser marked | Requires highly polished mould surfaces and careful ejection design to prevent adhesion |

Zinc Die Casting Applications

Zinc die casting is extensively used across a wide range of industries due to its excellent mechanical properties, precision, and cost-effectiveness. Key application areas include:

- Automotive: Components such as housings, brackets, and connectors that require strength and corrosion resistance.

- Electronics: Precision parts for connectors, housings, and small intricate components.

- Telecommunications: Casings and structural parts for devices and network equipment.

- Home Appliances: Durable parts for appliances like washing machines, refrigerators, and kitchen devices.

- HVAC Systems: Components including valves, fittings, and control housings.

- Agricultural Machinery: Robust parts designed for harsh outdoor environments.

- Medical Devices: Components requiring tight tolerances and reliability.

- Smart Home & Security: Precision parts used in sensors, locks, and smart devices.

- Industrial Equipment: Structural and functional components for machinery.

- Sports Equipment: Durable parts used in various sports gear.

- Domestic Appliances: Everyday household items needing high-quality metal parts.

- Fittings and Connectors: Essential for plumbing, electrical, and mechanical assemblies.

- Agriculture & Gardening: Parts designed for tools and machinery used in farming and gardening.

Zinc Die Casting Process

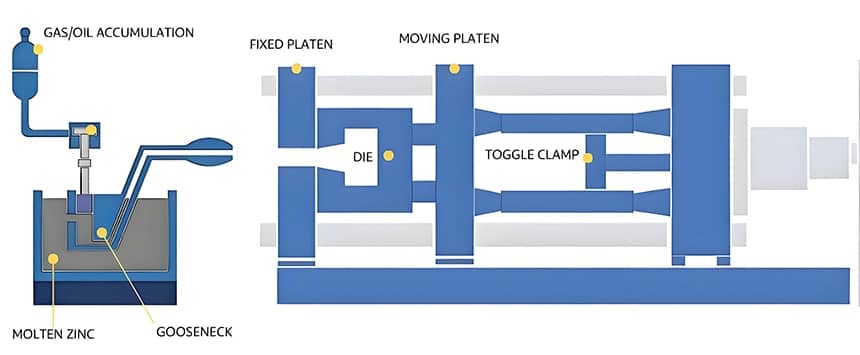

We use both hot and cold chamber die casting processes:

-

- Hot Chamber: Zinc is injected into the die through a gooseneck submerged in molten metal, allowing for efficient production with a high output rate.

- Cold Chamber: Molten zinc is manually poured into a cold chamber, and a plunger forces it into the die cavity under high pressure.

Both processes ensure high-quality parts with minimal production time.

<

Zinc die casting reduced variability, cost, and lead time by more than 50%.

Assembly & Installation Services

For projects requiring specific assembly or installation needs, DSW offers custom solutions, including:

- Casting pins directly into the component’s design

- Machining external threads on casting bosses

- Casting holes for internal threading

- Post-machining insert installations (e.g., pins, helicoils)

- Complex Assemblies and Kitting

- Custom Coating and Finishing

- Full assembly services

Why Choose DSW?

Whether you need complex geometries or highly specialized materials, DSW is equipped to deliver high-quality, custom solutions tailored to your needs.

- Expert Engineering: Our team supports you throughout the design and manufacturing process.

- Superior Quality Control: We ensure precision in every part.

- Fast Turnaround: We meet your deadlines with reliable delivery times.

Custom Zinc Die Casting

Looking for high-quality zinc die casting? Contact DSW today to discuss your project and receive a detailed quote.