Stress relief tempering is a critical process for maintaining and restoring die casting moulds. Residual stresses from EDM machining and prolonged production cycles can lead to cracks, deformation, and reduced service life. Through controlled heat treatment, these stresses are relieved, ensuring dimensional stability, microstructural integrity, and extended mould lifespan.

In this article, we examine:

- How stress forms within die casting moulds

- How tempering effectively removes that stress

What Causes Stress in Die Casting Moulds

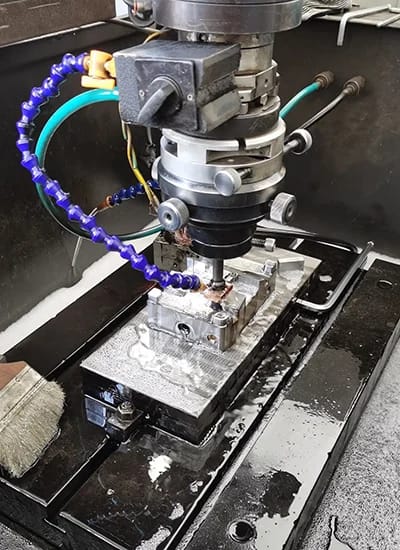

EDM-Induced Thermal and Structural Stress

Electrical Discharge Machining (EDM) removes material using high-temperature plasma, allowing precision but introducing significant stress due to thermal gradients.

- Extreme Temperature Gradients: Surface layers expand rapidly while the core remains cool, causing high compressive stress.

- Rapid Quenching: The dielectric fluid cools molten material suddenly, forming tensile stress in the surface.

- White Layer Formation: The brittle surface zone has high hardness but poor ductility, adding internal stress.

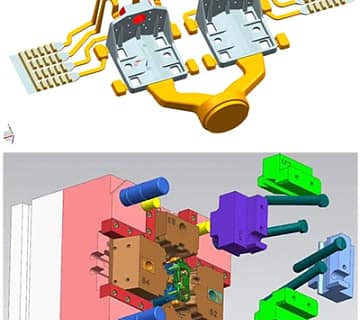

Service-Induced Stress from Thermal Fatigue and Mechanical Load

- Cyclic Thermal Fatigue: During each casting cycle, the mould cavity surface is exposed to molten metal at temperatures typically ranging from 600°C to 700°C (for aluminium, magnesium, and zinc alloys). This rapid heating causes the surface to expand quickly, while the core of the mould remains comparatively cool. When the mould opens and a release agent is applied, the surface cools and contracts suddenly. These repeated cycles of rapid expansion and contraction generate alternating compressive and tensile thermal stresses, which, over time, can initiate and propagate thermal fatigue cracks.

- Mechanical Stress: Injection pressure and moving parts like ejector pins add stress concentration.

- Microstructural Evolution: Carbide precipitation and matrix changes disturb internal equilibrium over time.

The Role of Tempering in Stress Relief

How Tempering Works at the Atomic Level

Tempering heats the steel to 560–650°C (H13 steel), allowing atoms to move and rearrange. Lattice distortions are relieved, reducing residual stress.

Transformation of Unstable Microstructures

Quenched martensite and EDM-induced white layers convert into tempered sorbite or troostite, eliminating brittle zones and restoring toughness.

Viscoelastic Relaxation and Plastic Flow

At high temperature, the steel’s yield strength drops temporarily. Internal stresses exceed the reduced yield point, causing slight plastic flow and dissipating stored strain energy. Slow cooling then stabilises the steel.

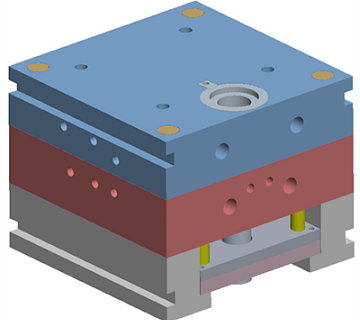

Key Parameters in Stress Relief Tempering

Temperature Control

Higher tempering temperature enables thorough stress relaxation but must not exceed original tempering temperature to avoid reduced hardness.

Holding Time

Sufficient soaking time ensures uniform heat distribution for complete stress relief, even in thick mould sections.

Controlled Cooling Rate

Slow, uniform cooling prevents reintroduction of thermal gradients and residual stresses.

Stress Relief at Different Stages

After EDM

- Type: Stabilisation tempering

- Effect: Eliminates EDM-induced stress, stabilises white layer, prevents microcracks

After Service

- Type: Recovery / Stress Relief

- Effect: Releases accumulated stress, restores microstructure, delays thermal fatigue crack propagation, extends mould life

Tempering Effects on Die Casting Mould Stress

| Stress Source | Tempering Type | Impact on Mould |

|---|---|---|

| EDM Processing | Stabilisation Tempering | Relieves EDM-induced stress, stabilises the white layer, and prevents surface microcracks |

| Operational Service | Recovery / Stress Relief Tempering | Removes accumulated internal stress, restores microstructural balance, and prolongs mould service life |

Conceptual Analogy

Internal stress in a mould is like a bent spring. Tempering gently heats it, allowing the spring to relax and return to its natural shape. When cooled gradually, the steel retains this stable configuration, with significantly reduced residual stress. This process effectively “heals” the mould’s internal strain, enhancing dimensional stability, thermal resistance, and overall service life, thereby ensuring reliable and consistent performance across prolonged production cycles.

Conclusion

Properly executed stress relief tempering is essential for precision die casting moulds. It improves dimensional stability, prevents early failure, and extends tool life. By understanding stress formation and applying tempering correctly, manufacturers can maintain consistent casting accuracy and superior performance across extended production runs.

TECHNICAL QUESTIONS

Frequently asked questions

Stress comes from EDM-induced thermal shock, the brittle white layer, cyclic thermal fatigue, and mechanical impact during service.

Controlled heating allows atomic rearrangement and microstructural stabilisation, relieving residual stress and improving toughness.

Typically 560–650°C, followed by slow, uniform cooling to prevent new stress formation.

For H13 tool steel, stress relief is achieved by slowly heating the material to a temperature between 565°C and 676°C (1050–1250°F). The steel is then held at this temperature to ensure uniform heat distribution before being gradually cooled in air, allowing internal stresses to be safely relieved.

No comment