Understanding the differences between die casting and plastic injection mold design is essential for manufacturers aiming to achieve efficiency, consistency, and cost savings in mass production.

While both methods use precision-engineered molds with core, cavity, gating, cooling, and ejection systems, their operating principles, materials, and performance demands differ significantly.

A clear understanding of these distinctions helps:

- Improve overall product quality and surface finish

- Extend mold lifespan through proper material selection

- Reduce production time and manufacturing costs

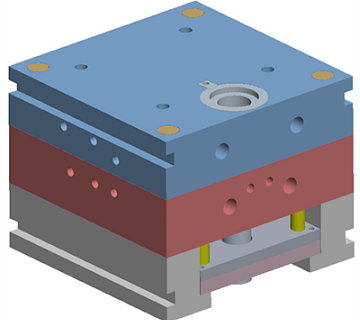

Detailed construction of a plastic injection mold used for precision molding.

Construction of a die casting mold designed for aluminum and zinc alloy production.

Main Differences: Die Casting vs. Plastic Injection Mold

Comparing Process Principles and Design Characteristics

Although both processes share the same basic mold structure, their operating conditions and material behaviors vary dramatically.

| Process | Material Type | Temperature & Pressure | Shrinkage Behavior | Design Focus |

|---|---|---|---|---|

| Plastic Injection Molding | Thermoplastics / Thermosets | Moderate | High shrinkage sensitivity | Uniform wall design and dimensional stability |

| Die Casting | Aluminum, Zinc, Magnesium alloys | High temperature and pressure | Low and predictable shrinkage | Thermal shock resistance and strength |

Key takeaway:

The fundamental difference between die casting vs. plastic injection mold design lies in the material behavior under temperature and pressure. Injection molding focuses on managing shrinkage and cooling, while die casting prioritizes structural integrity and thermal performance.

Runner and Gate Design in Die Casting vs. Injection Molding

Controlling Flow and Material Efficiency

Runner and gate design are crucial to both injection mold design and die casting tooling, directly influencing material flow, cycle time, and part quality.

| Feature | Injection Mold | Die Casting Mold |

|---|---|---|

| Runner size | Balanced to minimize material waste | Larger to prevent pressure loss during metal flow |

| Gate thickness | Thin and optimized for polymers | Thin but wide (0.3–0.8 mm) for molten metal |

| Material reuse | Regrind limited to 10–20% | Overflow and runner metal are 100% recyclable |

Die casting relies on overflow wells and runner traps to capture impurities and ensure consistent metal flow, improving both surface finish and dimensional precision.

Venting System and Air Release Design

Ensuring Quality by Managing Gas Entrapment

Proper venting plays a vital role in both processes.

In die casting, molten metal fills cavities extremely fast and under high pressure, making gas removal even more critical.

| Injection Mold | Die Casting Die |

|---|---|

| Micro vents near parting line | Venting channels combined with overflow wells |

| Lower gas entrapment risk | Vents transition from thick to thin to enhance release |

Effective venting design eliminates porosity, burn marks, and surface defects, ensuring consistent quality for both plastic and metal components.

Cooling System and Thermal Management

Improving Cycle Time and Mold Durability

In any mold tooling comparison, cooling system design is one of the most important factors influencing production efficiency and tool longevity.

| Feature | Plastic Injection Mold | Die Casting Mold |

|---|---|---|

| Cooling function | Controls shrinkage and stabilizes polymer cooling | Protects against thermal shock and fatigue |

| O-rings | Standard type | High-temperature resistant O-rings required |

| Nozzle layout | Embedded within mold | Exposed for easy maintenance and inspection |

In die casting, cooling channels must quickly dissipate extreme heat to prevent cracking and ensure long mold life.

Mold Steel and Structural Strength Comparison

Choosing the Right Tool Steel for Each Process

Tool steel selection determines mold performance, precision, and lifespan.

Because die casting operates under harsher conditions, it demands more robust materials and heat treatment than injection molds.

| Factor | Plastic Injection Mold | Die Casting Mold |

|---|---|---|

| Recommended steel grades | P20 / 718 / S136 | H13 / 8407 / 2344 ESR (heat-treated) |

| Core & cavity thickness | Standard | ~20 mm thicker for durability |

| Heat treatment | Optional | Mandatory for thermal resistance |

Die casting molds must resist thermal shock and high injection pressure, requiring premium-grade, heat-treated steels. Injection molds, meanwhile, prioritize polishability and corrosion resistance.

Alignment and Positioning Precision

Preventing Flash and Maintaining Fit Accuracy

In die casting vs. plastic injection mold design, alignment precision is critical.

Because molten metal is injected under extreme pressure, die casting molds use tapered or angled positioning systems instead of zero-degree alignment to reduce wear and maintain consistent closure throughout production cycles.

Ejection System Design

Managing Shrinkage and Part Release Forces

Metal contracts more during cooling than plastic, making ejection force a critical factor in die casting. Properly aligned ejector systems prevent deformation and ensure smooth demolding.

| Feature | Plastic Injection Mold | Die Casting Mold |

|---|---|---|

| Ejector pin layout | Standard configuration | Precisely matched to machine’s ejector rods |

| Ejection force | Moderate | High, due to strong metal adhesion |

| System type | Smooth mechanical ejection | Reinforced mechanical system for high pressure |

Accurate ejection design ensures long-term mold reliability and prevents damage during continuous production cycles.

Conclusion

Although both methods share structural similarities, die casting and plastic injection molding serve different purposes in industrial manufacturing.

Understanding these differences allows engineers and manufacturers to:

- Select the right mold type based on material and production volume

- Improve product quality and dimensional consistency

- Enhance tooling life and reduce operational costs

- Achieve optimized mass-production efficiency

By mastering both processes, you gain full control over performance, quality, and cost-effectiveness in modern mold tooling design.

No comment