Understanding Dies and Molds: A Buyer’s Guide for Die Vs Mold

If you’re sourcing parts or components internationally, knowing the difference between dies and molds is essential. These tools are the backbone of manufacturing, turning raw materials into high-quality finished products. Understanding the types, uses, and regional terms can help you communicate clearly with suppliers and ensure the best results for your production needs.

What Is a Die?

A die is a specialized tool used to cut, shape, or form material under pressure. Dies are commonly used with metals, but they can also be used for certain plastics. In manufacturing, dies are crucial for producing consistent, precise parts at high volume.

Common die applications include:

- Metal stamping dies – create flat or shaped metal components.

- Die casting dies – form complex metal parts quickly and accurately.

- Forging dies – produce strong and durable metal components.

For buyers, knowing the type of die your supplier uses helps ensure your parts meet exact specifications and quality standards.

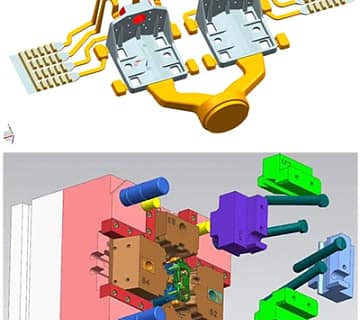

Example of a Typical Die Casting Die

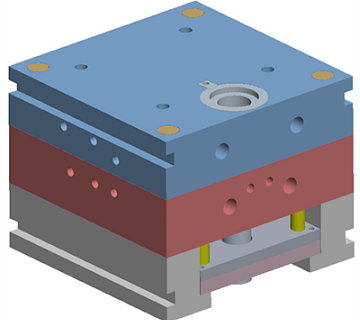

What Is a Mold?

A mold is a cavity or form used to shape material by pouring or injecting it until it solidifies. Molds are mostly used with plastics, rubber, glass, and ceramics. They allow manufacturers to produce detailed, high-precision components with consistent quality.

Common mold applications include:

- Injection molds – for consumer products, automotive components, and medical devices.

- Blow molds – for bottles, containers, and hollow parts.

- Compression and transfer molds – for rubber, composites, and specialty materials.

For buyers, selecting the right mold ensures your products are consistent, durable, and visually appealing.

Types of Dies and Molds -Die Vs Mold

Dies:

- Blanking dies: cut metal into shapes.

- Progressive dies: perform multiple forming steps automatically.

- Die casting dies: shape molten metal precisely.

Molds:

- Injection molds: produce plastic parts efficiently.

- Blow molds: create hollow containers.

- Compression molds: for rubber or composite products.

Synonyms and Regional Terms

When communicating internationally, you may see different terms:

- Die: press tool, stamping tool, die casting tool

- Mold: form, cavity, molding tool

Regional spelling differences:

- US: Mold & Die

- UK/Commonwealth: Mould & Die

- Germany/Japan: Die or Werkzeug (tool)

Need precision dies and molds?

Choose DSW for reliable dies and molds — backed by 21+ years of expertise and global reputation.

Key Differences Between Dies and Molds

| Feature | Die | Mold |

|---|---|---|

| Material | Metal (mostly) | Plastic, rubber, glass, ceramics |

| Process | Cutting, stamping, forging | Pouring, injecting, pressing |

| Output | Shapes material by removing or deforming | Shapes material by filling a cavity |

| Volume | High precision, repetitive | High precision, repeatable |

Tip: The die casting die is quite similar to an injection mold in terms of overall construction and components, as both feature cavities, cores, ejector systems, and cooling channels to produce precise, repeatable parts. However, important differences exist in their construction due to the materials they process and the specific requirements of each method.

Difference in Construction: Die Casting Die vs. Injection Mould

| Aspect | Die Casting Die | Injection Mould |

|---|---|---|

| Process Material | Molten metal alloys (aluminium, zinc, magnesium). | Molten thermoplastics or thermosets. |

| Operating Temperature | Very high (up to 700 °C for aluminium, ~400 °C for zinc). | Lower (typically 200–350 °C for plastics). |

| Material of Tool | High-strength hot-work tool steels (e.g., H13, SKD61) for thermal fatigue resistance. | Tool steels (P20, H13, S136) or sometimes aluminium for prototypes. |

| Main Construction Elements | – Core & Cavity Inserts (thicker, robust). – Die Base. – Sprue, Runner, and Gate designed for high-pressure molten metal. – Cooling channels (limited, since die absorbs heat). – Vent system to release air/gas. – Ejector system for solidified metal part. | – Core & Cavity Inserts (precisely machined, often polished). – Mould Base. – Sprue, Runner, Gate optimized for plastic flow. – Cooling channels (very important for cycle time). – Ejector system (pins, sleeves, stripper plates). – Vent system for air escape. |

| Cavity Surface Finish | Tough but not mirror-polished (surface roughness acceptable depending on casting). | Highly polished or textured (depending on plastic part appearance). |

| Cavity Pressure | Extremely high (up to 100–150 MPa). Requires heavy clamping force. | Lower (typically 40–100 MPa). |

| Shot Sleeve / Injection System | Has a shot sleeve + plunger/piston system to force molten metal into cavity. | Uses a plasticising screw + nozzle to inject molten plastic. |

| Thermal Management | Die must withstand thermal shock & soldering from hot metal. Cooling is slower. | Cooling is highly engineered with water/oil channels for rapid cycle times. |

| Cycle Time | Longer (metal solidification takes time). | Shorter (plastic solidifies quickly). |

| Typical Applications | Automotive housings, aerospace parts, engine components, electronic enclosures (metal). | Consumer goods, automotive interiors, electronics housings, packaging, medical devices (plastic). |

Why Buyers Should Care

- Clarity in communication: Using the correct term avoids confusion when ordering or specifying parts.

- Quality assurance: Understanding the tool type helps ensure the right tolerances, strength, and appearance for your products.

- Global sourcing: Suppliers may use different terms depending on the country—knowing the difference gives you an edge in negotiations and quality checks.

No comment