Introduction

Cold shut is a common defect in aluminum die casting parts, often affecting surface integrity, mechanical performance, and overall part quality. It appears as a visible line or seam on the casting surface where two streams of molten metal fail to fuse properly. If not addressed, cold shut can reduce strength, create leak paths, and lead to part rejection.

Understanding its causes, detection methods, and preventive measures is essential for engineers, mold designers, and manufacturers striving for high-quality aluminum die castings.

What is Cold Shut?

A cold shut occurs when separate flows of molten aluminium solidify before merging completely, leaving a distinct line or small gap on the casting surface. It often develops in regions far from the gate, where the metal cools rapidly or flow paths are long.

Appearance

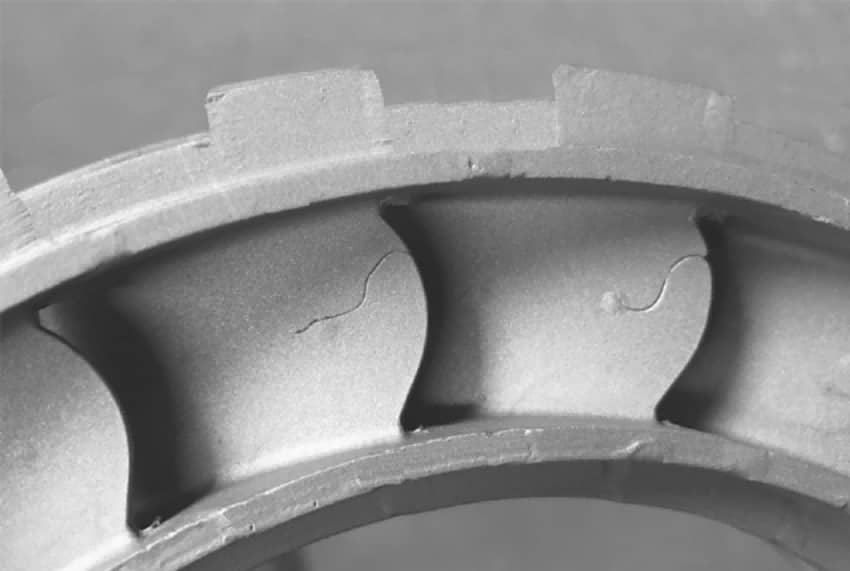

- Visual Characteristics: Cold shuts appear as irregular, often visible lines or cracks on the surface of the cast part. These lines are usually shiny and can be seen as a clear demarcation where the metal streams did not properly blend.

- Surface Texture: The affected areas may have a rough texture compared to the surrounding regions. Sometimes, the defect might create a noticeable depression or a weak spot on the surface.

- Size and Location: Cold shuts can vary from small and localized to large and more severe. They are typically found in areas where the metal flow is restricted or where two metal streams converge.

Cold Shut in Aluminum Die Casting Parts

Cold shut defects are fairly common in aluminum die casting, especially when the casting process isn’t fine-tuned. These defects usually happen in specific conditions like low temperatures, slow injection speeds, poor mold design, or suboptimal alloy mixtures. Thin-walled sections, complex shapes, or parts with long flow paths are more prone to cold shuts because the metal can cool and harden before properly merging. Parts like intricate housings, thin structural components, or designs with sharp details are especially at risk of this defect.

Why Does Cold Shut Occur?

- Low Temperatures: If the molten metal or the mold is too cold, the metal can solidify before fusing correctly with other flows.

- Poor Alloy Composition: Low fluidity alloys struggle to fill the mold completely, leading to incomplete fusion.

- Separate Metal Flows: A cold shut can form when metal flows separately in the mold and doesn’t merge properly.

- Improper Gating Design: A poorly designed gating system can cause uneven flow, leading to cold shuts.

- Inadequate Filling Speed or Venting: Slow filling speeds and poor venting can create air pockets, preventing proper fusion.

4. Detection and Inspection

Detecting cold shut is critical for maintaining casting quality. Common methods include:

- Visual Inspection: Look for surface lines, seams, or color variations.

- Dye Penetrant Testing: Reveals surface-breaking cold shuts not visible to the naked eye.

- X-ray Inspection: Identifies internal cold shut or weak bonding in critical structural areas.

- Mechanical Testing: Parts may fail tensile or fatigue testing if cold shuts are present internally.

How to Prevent Cold Shut Defects?

5.0 Optimize Melt and Mold Temperature

Maintain appropriate molten aluminum temperature and preheat the mold to ensure uniform solidification.

5.1 Adjust Alloy Composition

Use alloys with better fluidity to ensure the metal flows smoothly into all mold sections.

5.2 Improve Flow Dynamics

- Increase injection speed and pressure

- Use a well-designed runner and gate system

- Ensure smooth, straight flow paths to minimize turbulence

5.3 Adjust Gate Positioning

Strategically locate gates to promote balanced filling and reduce the likelihood of streams meeting at low temperatures.

5.4 Venting and Degassing

Proper mold venting prevents air entrapment, while degassing the aluminum melt reduces oxide formation.

5.5 Use Mold Flow Simulation

Advanced simulation software allows engineers to predict potential cold shut areas and adjust mold design and process parameters before production.

Why It Matters for You: Understanding and preventing cold shut defects is crucial for ensuring high-quality aluminum casting parts. For purchasing managers, selecting suppliers who prioritize defect prevention and maintain rigorous quality standards can lead to more reliable products, fewer returns, and better overall satisfaction.

No comment