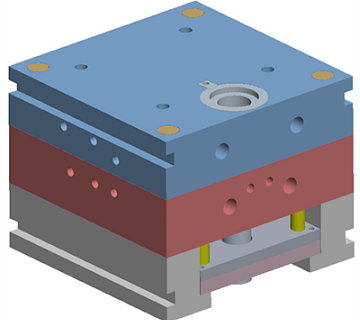

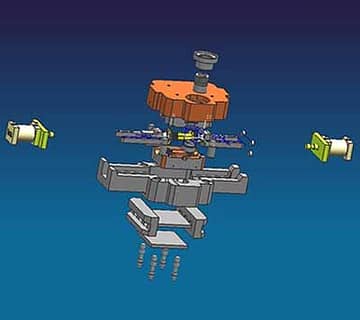

Standard Mould Components and Their Specifications

When it comes to the precision, efficiency, and longevity of injection moulds and die casting tools, every detail matters. Mould components form the structural and functional foundation of these tools, ensuring the proper shaping, ejection, cooling, and alignment of parts during the moulding process. In this guide, we present a comprehensive list of 92 standard mould components, their typical materials, treatments, and primary functions in industrial applications.

| No. | Item | Component Name | Other Name | Material | Heat Treatment | Usage |

|---|---|---|---|---|---|---|

| 1 | Mold Base | Top Plate | Press Plate / Top Tool / Upper Plate | S50C | None | Structural support for upper mold assembly. |

| 2 | Fixed Plate | A Plate | Cover Plate | S50C, P20 | None | Holds cavity, forms stationary half of mold. |

| 3 | Moving Plate | B Plate | Ejector Plate | S50C, P20 | None | Holds core and moves during part ejection. |

| 4 | Rail | Spacer Block | Bar | S50C | None | Supports mold movement and maintains alignment. |

| 5 | Ejector Plate | S50C, P20 | None | Pushes molded parts out of cavities during ejection. | ||

| 6 | Ejector Retainer Plate | S50C | None | Secures ejector pins and evenly distributes force. | ||

| 7 | Bottom Plate | Bottom Clamping Plate | Back Plate | S50C | None | Supports mold base and provides clamping area. |

| 8 | Molding System | Cavity Insert | Cover Die Insert | H13, 8407, Dievar, 2344ESR, DAC, DAC10 | HRC 44-48 | Forms cavity surface shaping molten material. |

| 9 | Core Insert | Ejector Die Insert | H13, 8407, Dievar, 2344ESR, DAC, DAC10 | HRC 44-48 | Forms core and internal part features. | |

| 10 | Slide Insert | Slide Core / Slide Tip / Slide Nose / Slide Front / Slide Face | H13, 8407, Dievar, 2344ESR, DAC, DAC10 | HRC 44-48 | Enables side actions for complex geometries. | |

| 11 | Cavity Sub-insert | Cover Die Sub-insert | H13, 8407, Dievar, 2344ESR, DAC, DAC10 | HRC 44-48 | Supports secondary cavity surfaces. | |

| 12 | Core Sub-insert | Ejector Die Sub-insert | H13, 8407, Dievar, 2344ESR, DAC, DAC10 | HRC 44-48 | Supports secondary core features. | |

| 13 | Cavity Pin | Cavity Insert Pin | SKD61 | HRC64-68 / 40-45 | Secures cavity inserts and positioning. | |

| 14 | Core Pin | Core Insert Pin | SKD61 | HRC64-68 / 40-45 | Secures core inserts for accuracy. | |

| 15 | Slide Pin | SKD61 | HRC64-68 / 40-45 | Guides sliding components during mold operation. | ||

| 16 | Date Pin | Date Code Pin | SKD61 | HRC64-68 / 40-45 | Used to imprint date codes on molded parts. | |

| 17 | Lifter Insert | H13, 8407, Dievar, 2344ESR, DAC, DAC10 | HRC 44-48 | Enables ejection of undercut features. | ||

| 18 | Ejector Sleeve Pin | Ejector Sleeve | SKD61 | HRC64-68 / 40-45 | Supports ejector sleeve alignment and movement. | |

| 19 | Injection System | Cavity Runner Plate | FH Runner Plate | H13 | HRC 44-48 | Directs molten metal into cavities efficiently. |

| 20 | Core Runner Plate | MH Runner Plate | H13 | HRC 44-48 | Channels molten metal to core side of mold. | |

| 21 | Cavity Chill Vent | FH Chill Vent | H13 | HRC 44-48 | Prevents gas build-up by venting mold cavities. | |

| 22 | Core Chill Vent | MH Chill Vent | H13 | HRC 44-48 | Allows gas escape from core sections. | |

| 23 | Sprue Bush Fixing Plate | H13 | HRC 44-48 | Secures sprue bush and supports gate area. | ||

| 24 | Sprue Spreader Fixing Plate | H13 | HRC 44-48 | Supports sprue spreader and stabilizes molten flow. | ||

| 25 | Sprue Bush | H13 | HRC 44-48 | Channels molten metal from injection nozzle. | ||

| 26 | Sprue Spreader | Shot Post | H13 | HRC 44-48 | Distributes molten metal evenly into runners. | |

| 27 | Shot Sleeve | Shot Chamber | H13 | HRC 44-48 | Houses plunger to inject molten metal into mold. | |

| 28 | Shot Block | H13 | HRC 44-48 | Supports shot sleeve and injection mechanism. | ||

| 29 | Components | Slide Carrier | H13 | HRC 44-48 | Holds and guides sliding mold components. | |

| 30 | Slide Cam | Wedge Block / Jaw | H13 | HRC 44-48 | Controls slide movement during mold cycle. | |

| 31 | Gib | H13 | HRC 44-48 | Prevents lateral movement in sliding components. | ||

| 32 | Wear Plate | H13 | HRC 44-48 | Protects mold surfaces from wear and abrasion. | ||

| 33 | Slide Guider | Slide Guiding Way | H13 | HRC 44-48 | Ensures precise slide alignment and smooth travel. | |

| 34 | Stop Plate | S50C | None | Limits mold opening or slide travel. | ||

| 35 | Slide Stop Plate | S50C | None | Stops slide at designed position. | ||

| 36 | Name Plate | Mold Plaque / Tool Designation / ID Plate | S50C | None | Identifies mold or tooling information. | |

| 37 | Mount Plate | Support Plate / Dead Plate / Retainer Plate | S50C | None | Supports and secures mold components. | |

| 38 | Cylinder Support Plate | Cylinder Mount Plate | S50C | None | Supports hydraulic or pneumatic cylinders. | |

| 39 | Spring Bush Mount Plate | S50C | None | Holds spring bushings in position. | ||

| 40 | Spring Housing | Spring Sleeve / Spring Pocket | S50C | None | Encases springs providing retention and guidance. | |

| 41 | Pull Rod Sleeve | H13 | HRC 44-48 | Protects pull rods from wear and damage. | ||

| 42 | Connector | Coupler | S50C | None | Joins mold components or parts of the assembly. | |

| 43 | Lock Plate | Lock Block | S50C | None | Secures mold components to prevent movement. | |

| 44 | Rotation-stop Block | S50C | None | Prevents unwanted rotation of mold parts. | ||

| 45 | Locating Ring | S50C | None | Ensures accurate mold positioning in the press. | ||

| 46 | Balance Block | S50C | None | Balances mold weight and forces during operation. | ||

| 47 | Support Pillar | S50C | None | Supports mold structure to maintain rigidity. | ||

| 48 | Support Plate | Support Bracket | S50C | None | Reinforces mold assembly for stability. | |

| 49 | Cover Plate | S50C | None | Covers and protects mold components. | ||

| 50 | Press Block | S50C | None | Absorbs pressing forces during mold closing. | ||

| 51 | Lifter Base | H13 | HRC 44-48 | Base for lifter mechanisms ejecting undercuts. | ||

| 52 | Positioning Block | Locating Block | H13 | HRC 44-48 | Ensures precise positioning of mold parts. | |

| 53 | Water Jacket | S50C | None | Circulates cooling water to regulate mold temperature. | ||

| 54 | Shim | Pad | S50C | None | Used for precise spacing and alignment adjustments. | |

| 55 | Heel Block | Cushion Block | S50C | None | Absorbs impact and wear at contact points. | |

| 56 | Limit Block | Limit Boss | S50C | None | Restricts travel or movement of mold components. | |

| 57 | Fixing Pole | S50C | None | Secures components in fixed positions. | ||

| 58 | Induction Block | S50C | None | Facilitates induction heating for mold parts. | ||

| 59 | Water Tower | Water Manifold | S50C | None | Distributes cooling water through the mold system. | |

| 60 | Piston Pillar | S50C | None | Supports pistons in hydraulic or pneumatic systems. | ||

| 61 | Connecting Rod | H13 | HRC 44-48 | Transfers motion in mechanical linkages within the mold. | ||

| 62 | Standard Mold Components | Guide Pin | SUJ2 | HRC 58-62 | Ensures accurate alignment of mold halves. | |

| 63 | Guide Bush | SUJ2 | HRC 58-62 | Supports guide pins and reduces wear. | ||

| 64 | Return Pin | SUJ2 | HRC 58-62 | Facilitates ejector system reset after part release. | ||

| 65 | Ejector Pin | Ejector | SKD61 | HRC 64-68 / 40-45 | Directly pushes the molded part out of the cavity. | |

| 66 | Ejector Guide Pin | SUJ2 | HRC 58-62 | Guides ejector pins for smooth movement. | ||

| 67 | Ejector Guide Bush | SUJ2 | HRC 58-62 | Provides low friction path for ejector pins. | ||

| 68 | Spot Cooling | Jet Cooling | Standard (STD) | None | Targets specific mold areas for temperature control. | |

| 69 | Plug | Standard (STD) | None | Seals mold cooling channels or holes. | ||

| 70 | Baffle | Standard (STD) | None | Directs coolant flow within the mold. | ||

| 71 | Spring | Standard (STD) | None | Provides force for ejector or lifter mechanisms. | ||

| 72 | Screw Bolt | S50C | None | Fastens mold components securely. | ||

| 73 | Eyebolt | Standard (STD) | None | Used for lifting and handling mold assemblies. | ||

| 74 | Water Tube | Water Pipe | Copper (Cu) | None | Conveys cooling water throughout the mold. | |

| 75 | Oil Tube | Oil Pipe | Standard (STD) | None | Transports oil for lubrication or hydraulic systems. | |

| 76 | Nipple | Standard (STD) | None | Connects pipes and tubes within the mold system. | ||

| 77 | Hexagon Nut | Hex Nut | Standard (STD) | None | Secures bolts and screws. | |

| 78 | Hexagon Nut with Flange Surface | Standard (STD) | None | Provides a larger bearing surface to distribute load. | ||

| 79 | Hexagonal Socket Head Cap Screw | SHCS | Standard (STD) | None | High strength fastening screw with hex socket drive. | |

| 80 | Flat Head Screw | Standard (STD) | None | Flush mounting screw for smooth surfaces. | ||

| 81 | Grub Screw | Standard (STD) | None | Used for locking components in position without protruding heads. | ||

| 82 | Round Head Screw | Standard (STD) | None | Common fastening screw with rounded head. | ||

| 83 | Hex Socket Head Shoulder Screw | Standard (STD) | None | Shoulder screw used for precise spacing or pivoting. | ||

| 84 | Hexagon Screw | Standard (STD) | None | General-purpose fastening screw with hex head. | ||

| 85 | Oil Cylinder | Standard (STD) | None | Hydraulic actuator for mold movement. | ||

| 86 | Limit Switch | Sensor Switch / Inductive Switch | Standard (STD) | None | Detects mold position and controls cycle operations. | |

| 87 | Stop Pin | Junk Nail | S50C | None | Prevents overtravel of mold components. | |

| 88 | Seal Ring | Standard (STD) | None | Ensures tight sealing in hydraulic or pneumatic areas. | ||

| 89 | Dowel Pin | SUJ1 | HRC 58-62 | Precise locating pin for component alignment. | ||

| 90 | Angle Pin | SUJ2 | HRC 58-62 | Secures components at specific angles. | ||

| 91 | Date Code | Standard (STD) | None | Used for tracking mold production dates. | ||

| 92 | Ejector Sleeve | FDAC | HRC 64-68 / 40-45 | Supports ejector pins and guides ejection. |

Importance of Standardisation

Using standard components simplifies tool design, reduces costs, and ensures easy replacement. Manufacturers like DME, Hasco, and Misumi offer global standards that can be referenced during procurement and assembly.

No comment