Porosity in ADC12(A383)Die Casting: Causes and Reduction Methods

ADC12 is a widely used aluminium alloy in die casting due to its strong mechanical properties, corrosion resistance, and good machinability. However, porosity in die casting—including gas porosity and shrinkage porosity—remains a common challenge, which can weaken parts and affect quality.

A383 alloy is similar to ADC12, offering excellent fluidity and corrosion resistance. It is ideal for thin-walled, complex castings used in automotive and electronics applications, ensuring dimensional accuracy and durability.

This article explains the main causes of porosity in casting, the different types of defects, and effective ways to reduce die cast porosity for higher-quality results.

What is Porosity in Aluminium Casting?

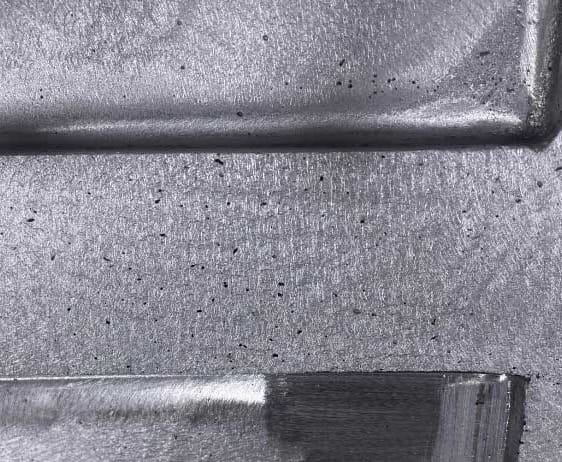

Porosity refers to voids, cavities, or holes within a casting’s metal structure. These imperfections can occur due to trapped air, shrinkage during solidification, or gases generated during the die casting. Porosity adversely affects the casting’s mechanical strength, surface finish, and pressure tightness, making its mitigation critical for high-performance applications.

Causes of Porosity in Die Casting

Aluminum Alloy ADC12 (A383)

- Gas Entrapment

- Source: Air can become trapped in the molten metal during injection or turbulence in the gating system.

- Impact: Leads to gas porosity with spherical voids throughout the casting.

- Primary Factors: High injection speeds, poor venting, or inadequate gating design.

- Appearance: Smooth, round, or spherical voids formed as gas bubbles solidify.

- Shrinkage Porosity

- Source: Occurs during cooling when material volume decreases and molten metal cannot fill voids.

- Impact: Irregular cavities, usually near thicker sections.

- Primary Factors: Improper mold design or uneven cooling rates.

Comparison of Gas Porosity and Contamination Porosity

| Factor | Gas Porosity | Contamination Porosity |

|---|---|---|

| Cause | Trapped gases, such as air or steam, during the injection process | Foreign particles or impurities present in the molten metal |

| Location | Typically located near the center or internal areas of the casting | Mostly near the surface where contaminants accumulate |

| Appearance | Small, spherical voids or smooth, rounded holes | Irregular, sharp-edged voids with rough or uneven boundaries |

| Impact on Material | Reduces material strength and durability, weakening the part | Compromises material integrity, may cause poor surface finish or internal defects |

| Prevention | Enhance venting, minimize moisture, and carefully control injection speed | Apply proper degassing and filtration; maintain clean equipment and handle metal carefully |

Mold Design Issues

- Poorly Designed Gating and Runners: These can cause turbulence or insufficient mold filling, increasing the risk of porosity.

- Inadequate Vents: Poorly vented moulds trap air and gases, creating porosity during solidification.

- Alloy Characteristics

- Source: The composition of ADC12 may release hydrogen or other gases during melting, contributing to gas porosity.

- Impact: Increases susceptibility to internal defects unless degassing is performed.

- Die Design and Process Conditions

- Source: Suboptimal runner and gate dimensions or insufficient mold venting.

- Impact: Causes air and gas to remain trapped during the casting cycle.

Methods to Reduce Porosity in ADC12 Die Casting

- Optimise Mould and Die Design

- Adequate Venting: Incorporate vents and overflow channels to allow trapped air and gases to escape.

- Gating System Improvements: Use well-designed runners and gates to minimize turbulence and air entrapment.

- Control Injection Parameters

- Moderate Injection Speeds: Avoid excessive speeds to reduce air turbulence.

- Balanced Pressure Control: Ensure consistent injection pressure to fill moulds evenly without introducing voids.

- Degassing

- Gas Removal: Use fluxes or an inert gas during melting to remove dissolved hydrogen from the molten metal.

- Vacuum-Assisted Casting: Employ vacuum technology to reduce the risk of gas porosity.

- Thermal Management

- Uniform Cooling: Use chills or cooling channels in the mold to ensure even solidification.

- Adjust Pouring Temperature: Maintain appropriate molten metal temperatures to minimise shrinkage effects.

- Material Handling and Preparation

- Proper Storage: Store raw materials in a dry location to prevent moisture contamination.

- Filtration: Use ceramic foam filters to remove impurities that might generate gas during casting.

Porosity Detection Methods

Advanced non-destructive testing methods are employed to identify and quantify porosity in castings:

- X-Ray Inspection: Reveals internal voids and defects without damaging the casting.

- Ultrasonic Testing: Detects variations in density that indicate porosity.

- Pressure Testing: Evaluate the leak-tightness of the casting, particularly for pressure-sensitive components.

How Does Porosity Affect Automotive Components?

Porosity, a common issue in die casting, can significantly impact automotive components’ performance, reliability, and longevity. It occurs when air pockets or voids form within the metal during the casting process, leading to reduced mechanical strength, potential leaks, and compromised structural integrity.

Automotive Components Commonly Made by Die Casting

Die casting is widely used in the automotive industry to produce high-precision and strong components. However, porosity in these parts can pose challenges, especially for critical applications. Below is a categorised list of automotive and truck components that rely on die casting:

1. Automotive Components

- Engine Components: Engine blocks, cylinder heads, throttle bodies, thermostat housings, bed plates, and oil sumps.

- Powertrain Parts: Clutch cases, torque converter housings, transmissions, and valve body castings.

- Air and Fuel Systems: Inlet manifolds, oil and fuel rails, pump bodies, and EGR hardware.

- Cooling Systems: Water pumps and timing chain covers.

- Forced Induction Systems: Turbochargers and superchargers.

2. Truck Components

- Heavy-Duty Engine Parts: Turbocharger housings, crankcases, and pistons.

- Chassis Components: Reinforcement brackets and cross members.

- Fuel System Parts: Diesel injector housings and fuel pump covers.

- Brake and Suspension Systems: Brake callipers, suspension mounts, and hubs.

3. Automotive Components

- Electric Vehicles (EVs): Battery enclosures and motor housings.

- Trailers: Hitch couplers, tow hooks, and axle mounts.

- Cab Components: Door handles, mirrors, and structural hinges.

Benefits of Die Casting for Automotive Applications

Die casting is preferred for its precision, strength, and cost-effectiveness, making it ideal for producing complex shapes with tight tolerances. Components benefit from high-dimensional accuracy, consistent quality, and reduced machining requirements.

However, managing porosity during the die-casting process is crucial to fully realise these advantages, especially in applications that demand high mechanical strength, leak resistance, and durability. Effective porosity control enhances the reliability of automotive components, thereby contributing to the development of safer and more durable vehicles.

Final Thoughts

Porosity in casting—including gas porosity, shrinkage porosity, and contamination porosity—is a significant quality challenge in ADC12 (A383) die casting. However, with optimized mold design, controlled injection parameters, proper melt treatment, and careful material handling, manufacturers can dramatically reduce porosity in aluminum casting and produce high-quality components.

By eliminating the root causes of casting porosity, die casters can achieve higher reliability, lower scrap rates, and superior product performance across automotive, electronics, and industrial applications.

No comment