Aluminum alloys are widely used in engineering because of their lightweight nature, corrosion resistance, and excellent strength-to-weight ratio. One of the most important mechanical properties that determines whether an alloy is suitable for load-bearing applications is its yield strength.

This article explains what yield strength is, why it matters for aluminum alloys, how it compares with other metals like steel, and provides a comprehensive chart of yield strength values for common aluminum alloys used in die casting and other manufacturing processes.

What is Yield Strength?

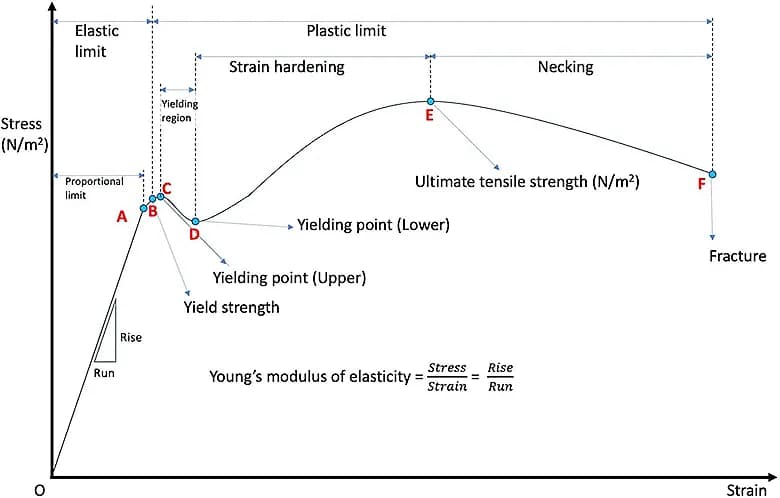

From an engineering perspective, yield strength is the maximum stress a material can withstand before it undergoes permanent deformation. In simple terms, it’s the point at which aluminum will no longer return to its original shape once the load is removed.

- Stress = Load applied per unit area (N/m², MPa, or ksi).

- If the applied stress stays below yield strength, the material behaves elastically and springs back.

- If the applied stress exceeds yield strength, the material deforms permanently.

⚖️ Tensile strength vs. yield strength:

- Tensile strength = maximum load a material can handle before fracture.

- Yield strength = load at which permanent deformation begins.

Both are important, but yield strength is critical for designing safe, long-lasting components.

| Feature | Yield Strength | Tensile Strength |

|---|---|---|

| Definition | The stress level at which a material undergoes irreversible plastic deformation. | The maximum stress a material can withstand before fracturing. |

| Position on Stress-Strain Curve | Occurs prior to the ultimate tensile strength (UTS) and marks the onset of plastic deformation. | Occurs at the peak of the curve, immediately before necking and failure. |

| Role in Design | Ensures dimensional stability by preventing permanent deformation under normal service loads. | Defines the maximum load capacity to prevent catastrophic failure under extreme stress. |

| Application Focus | Critical for precision components, structural frames, housings, and parts requiring strict deformation tolerance. | Essential for high-strength components such as fasteners, load-bearing members, and areas subject to sudden or peak loading. |

| Failure Behavior | Characterized by gradual deformation, often providing visible warning before failure. | Characterized by abrupt fracture with minimal warning once the maximum stress is exceeded. |

Engineering Perspective

- Yield strength is a measure of a material’s resistance to permanent deformation, serving as a key design parameter for ensuring serviceability and dimensional accuracy.

- Tensile strength represents the ultimate capacity of a material to withstand stress, serving as a critical benchmark for safety under extreme conditions.

Why Yield Strength Matters in Aluminum Alloys

Pure aluminum (99%+) has a relatively low yield strength of ~30 MPa (4 ksi). However, by adding alloying elements (copper, magnesium, silicon, zinc) and applying heat treatments (e.g., T4, T6), yield strength can reach 425+ MPa.

Yield strength directly affects:

- Load-bearing capacity – Can the component withstand forces without deformation?

- Structural reliability – Ensures dimensional accuracy over time.

- Material selection – Choosing the right alloy saves costs and avoids over-engineering.

Factors That Influence Aluminum Yield Strength

- Alloying Elements – Different series (2xxx, 5xxx, 6xxx, 7xxx) deliver different strength levels.

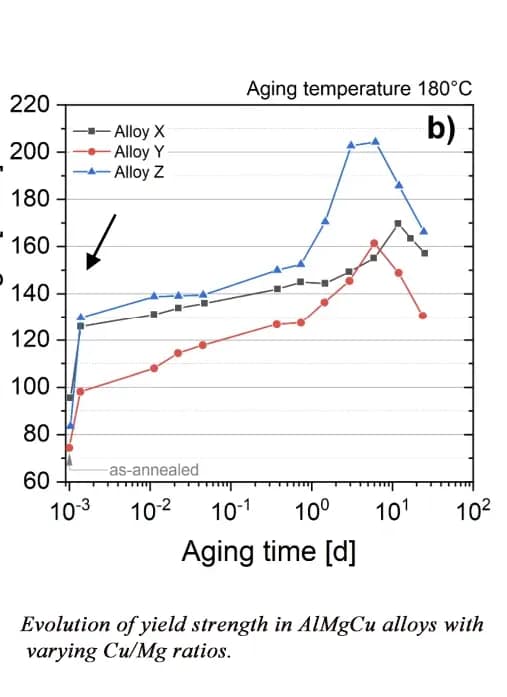

- Heat Treatment (T-designations) – Solution treatment, aging, and over-aging significantly change strength.

- Work Hardening (H-designations) – Cold working increases strength in non-heat-treatable alloys.

- Temperature – Yield strength decreases at elevated temperatures.

- Manufacturing Process – Die casting, forging, extrusion, or rolling can all affect strength.

Yield Strength of Common Aluminum Alloys

Below is a reference chart of popular aluminum alloys with their temper designations and yield strength values.

| Aluminum Alloy | Temper | Yield Strength (MPa) | Yield Strength (ksi) | Typical Applications |

|---|---|---|---|---|

| 1100 | H12 | 76 | 11 | Roofing, siding, chemical equipment |

| 2014 | T6 | 400 | 58 | Aerospace structures, automotive parts |

| 2024 | T3 | 290 | 42 | Aircraft components, transport vehicles |

| 2618 | T61 | 290 | 42 | Aerospace engines, motorsport |

| 3003 | H18 | 172 | 25 | Roofing, siding, cooking utensils |

| 5052 | H32 | 159 | 23 | Marine, pressure vessels, pipelines |

| 5056 | H38 | 345 | 50 | Rivets, marine hardware |

| 6061 | T6 | 241 | 35 | Aerospace, automotive, pipelines |

| 6063 | T6 | 172 | 25 | Architectural profiles, railings |

| 7050 | T74 | 414 | 60 | Aerospace, defence |

| 7075 | T6 | 483 | 70 | Aircraft, cycling, military-grade parts |

| A356 | T61 | 193 | 28 | Automotive, aerospace castings |

| AlSi9Cu3 | — | 160 | 23 | Die casting for automotive engines |

📌 Note: Yield strength varies with temperature and processing methods. Always consult alloy datasheets for design-critical applications.

Aluminum vs Steel Yield Strength

- Steel typically offers higher yield strength than aluminum.

- However, aluminum provides a superior strength-to-weight ratio, making it ideal for aerospace, automotive, and lightweight structures.

| Material | Alloy/Grade | Yield Strength (MPa) | Yield Strength (ksi) | Density (g/cm³) | Notes / Applications |

|---|---|---|---|---|---|

| Aluminum | Pure Al | 30 | 4 | 2.70 | Low-strength applications, lightweight parts |

| Aluminum | 6061-T6 | 241 | 35 | 2.70 | Aerospace, automotive, structural components |

| Aluminum | 7075-T6 | 483 | 70 | 2.81 | Aerospace, defence, high-strength lightweight parts |

| Steel | Mild Steel | 250 | 36 | 7.85 | Construction, general engineering |

| Steel | Structural Steel | 350 | 51 | 7.85 | Bridges, building structures |

| Steel | High-Strength Steel | 550 | 80 | 7.85 | Automotive chassis, high-load applications |

Exsample: High-strength aluminum alloys, such as 7075-T6 (483 MPa), offer yield strengths approaching that of mild steel, while weighing approximately one-third as much. This makes them an ideal choice for applications where both strength and lightweight performance are critical.

Applications of Aluminum Alloys by Yield Strength

- Lower yield strength alloys (100–200 MPa):

- Architectural elements, consumer goods, packaging, roofing sheets.

- Medium yield strength alloys (200–350 MPa):

- Automotive panels, pipelines, marine applications, industrial components.

- High yield strength alloys (350–480+ MPa):

- Aerospace frames, defence equipment, motorsport, precision engineering.

No comment